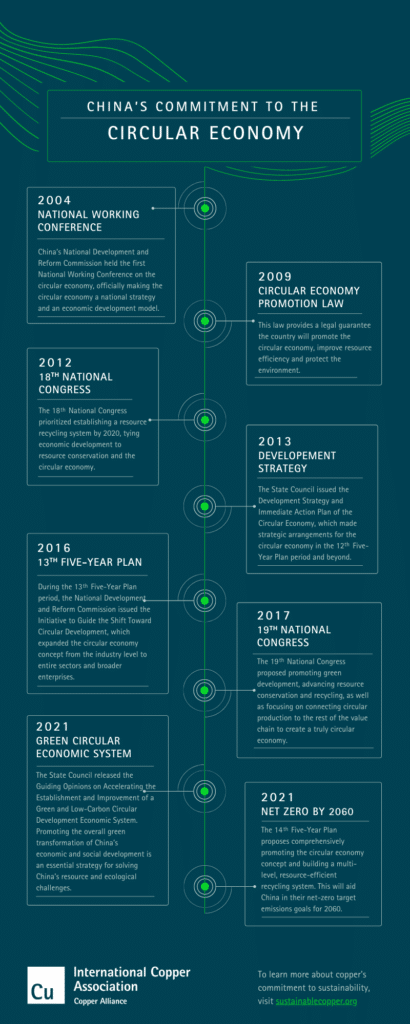

China has announced its net-zero target for carbon emissions by 2060. To meet this goal, China has been proactive during the 13th Five-Year plan pushing innovative policies that will influence the future of the country’s sustainability strategies. This effort has led to the successful development of the circular economy in China, and copper recycling has played a key role.

China’s copper recycling initiatives are essential to its ongoing sustainability approaches. By considering recent developments in circular economy policies and current trends in the copper recycling industry, China will be able to develop intentional strategies to meet its ambitious climate goals.

THE CURRENT STATE OF CHINA’S CIRCULAR ECONOMY POLICIES

During the 13th Five-Year Plan period (2016–2020), the National Development and Reform Commission (NDRC) issued the Initiative to Guide the Shift Toward Circular Development. The initiative expanded the circular economy concept from the industry level to include entire sectors and broader enterprises.

During this time, China also sought international collaboration in its circular economy goals. In 2018, Director He Lifeng of the NDRC and Vice President of the European Commission, Jyrki Katainen, jointly signed a Memorandum of Understanding on Cooperation in the Circular Economy under the witness of Premier Li Keqiang; President of the European Council, Donald Tusk; and President of the European Commission, Jean-Claude Juncker. Cooperation between China and the EU has enhanced bilateral exchanges regarding the circular economy and will continue to contribute to the implementation of the China-EU 2020 Strategic Agenda for Cooperation and the 2030 Agenda for Sustainable Development. Joint action will improve global resource efficiency and help all parties to achieve their sustainable-development goals.

The 14th Five-Year Plan (2021 – 2025) proposes comprehensively promoting the circular economy and building a multi-level, resource-efficient recycling system. In 2021, the State Council released the Guiding Opinions on Accelerating the Establishment and Improvement of a Green and Low-Carbon Circular Development Economic System, which states that progressing toward the development of a low-carbon circular economic system and a green transformation of economic and social development is an essential strategy for solving China’s resource, environmental and ecological challenges.

FOUR KEY TRENDS IN CHINA’S COPPER RECYCLING INDUSTRY

1. Strategic Patterns Taking Shape

After nearly 70 years of development, China’s copper recycling industry has grown in size and strength, transforming from labor-intensive processes to an innovative model of technologically driven practices. The formation of complete industrial clusters coupled upstream and downstream sectors in the Pearl River Delta, the Yangtze River Delta, the Bohai Rim and the Jiangxi regions. The coordination of the industrial chain enhanced the concentration of industrial initiatives and nurtured higher-quality enterprises. Specifically, enterprises above a designated scale account for more than 60 percent. The recycling industry developed into a strategic landscape in which large-scale enterprises take the lead and small and medium-sized enterprises contribute to the core of the industry.

2. Innovative Applications with Remarkable Results

Critical recycling processes, such as pretreatment, smelting and environmental protection technology, have made significant breakthroughs. China’s copper industry has implemented the latest scientific and technological innovations in copper recycling. Many enterprises have also used Kaldo furnaces and NGL furnaces for processing scrap copper, as well as production lines converting copper scrap to high-grade copper rods. Through these advanced applications, the smelting process of copper recycling and the resource conservation from electronic waste are becoming harmonized.

3. Improvement to Industrial Policies

China has continued to introduce new environmental protection policies and standards to promote copper recycling. China is committed to a comprehensive system of industrial policies. Efficient resource use, as well as upgrading and recycling automobiles, home appliances and consumer electronic products are top policy priorities. To accomplish these goals, China continues to promote the recycling of old products, extend the responsibility of manufacturers and roll out new policies, including the new Solid Waste Pollution Prevention and Control Law and the National Hazardous Waste List (2021 Edition). These policies also include the “waste-free cities” pilot program, industrial pollutant discharge standards and pollution permits, as well as commissioned nationwide research and development projects on solid waste. These efforts are of great significance for standardizing the development of copper resource recycling and pollution prevention in the recycling process.

4. Resource Conservation is a Shared Value

Given China’s scarce copper reserves, importing high-grade copper scrap is an indispensable part of China’s copper raw material supply system. China has established new standards for raw materials, including recycled brass and copper. With these new standards, China can import pre-processed, recycled raw materials arriving from overseas that meet these standards, helping China supplement demand.

China has prioritized the development of its circular economy and recycling management systems, making significant headway that will contribute to China’s ongoing and future sustainability strategies. The copper industry plays an essential role in the development of China’s circular economy. Through continued innovation in both policy and technology, China’s copper industry will be a central contributor to China’s recycling advancement and resource conservation.

Zhao Kai, MBA, Beijing University. Executive Vice President and Secretary General, China Association of Circular Economy. Zhao Kai provides expertise in leading and guiding government agencies on major circular economy and energy policymaking. He has studied and promoted energy-savings initiatives in China’s industrial and transportation fields for more than 15 years, particularly in the application of the high-efficiency motors, transformers, power cables and other electrical equipment. He is a member of several national policy and standard making committees and has received several prizes in these roles.

Zhao Kai, MBA, Beijing University. Executive Vice President and Secretary General, China Association of Circular Economy. Zhao Kai provides expertise in leading and guiding government agencies on major circular economy and energy policymaking. He has studied and promoted energy-savings initiatives in China’s industrial and transportation fields for more than 15 years, particularly in the application of the high-efficiency motors, transformers, power cables and other electrical equipment. He is a member of several national policy and standard making committees and has received several prizes in these roles.

About the Copper Alliance®

The Copper Alliance is a network of regional copper centers and their industry-leading members. It is responsible for guiding policy and strategy and for funding international initiatives and promotional activities. Headquartered in Washington, D.C., the organization has offices in three primary regions: Europe, Asia and North America. The Copper Alliance has partnerships and programs in more than 100 countries.