The European Copper Institute (ECI) joins with representatives from Europe’s renewable energy and energy-efficiency value chains in urging European leaders to combine the new stimulus packages with the EU Green Deal to restart Europe and drive its economy with a focus on energy efficiency and renewable energy across all sectors. For more information on the formal request and its signatories, click here.

Year in Review: Three Key Takeaways From 2019

As 2019 comes to a close, some clear trends can be observed. First, decarbonization has become more of a priority for governments and industries as a way to reduce emissions. Second, ensuring resources can be reused and recycled means the circular economy has also moved up to the top of the policy agenda around the world. Finally, as more resource extraction will be needed, the debate has also focused on how industry can do so in a responsible way; with some important initiatives being launched. Below are details on these three key takeaways from 2019.

Decarbonization is a priority

This year saw the move toward decarbonization become apparent as the world transitions to more sustainable energy sources and transportation. For example, the European Union finalized its Clean Energy for All Package that includes renewable energy and energy-efficiency targets and just recently published an outline of a European Green Deal that contains a goal to become carbon neutral by 2050. Meanwhile in the U.S., policies are being implemented to support the expansion of electric vehicles (EVs). This year the U.S. Senate Committee on Environment and Public Works and the House Energy & Commerce Committee approved nearly $2 billion for EV infrastructure through the America’s Transportation Infrastructure Act of 2019 (ATIA) and Leading Infrastructure for Tomorrow’s (LIFT) America Act respectively.

The move away from fossil fuels in the field of transportation is another aspect of decarbonization that is happening. Bloomberg New Energy Finance’s 2019 EV Outlook showed that the rise of EVs continues to be a global trend. Compared to 2010 when just a few thousand EVs were sold globally, over 2 million were sold in 2018. This figure is expected to reach 10 million in 2025. Furthermore, the report foresees that by 2040, 57 percent of global new passenger vehicle sales will be EVs, accounting for 30 percent of the global passenger vehicle fleet at that point.

These EVs will still need to be charged with electricity and ensuring that EVs run on renewable sources instead of fossil fuels is crucial. A rise in the uptake of renewables is happening. The International Energy Agency says renewable capacity will expand by 50 percent in the next five years alone.

Both of these developments mean more copper will be needed in the coming years as it is a key component in EVs (battery EVs can use from two to four times as much copper as traditional vehicles) and many renewable energy technologies. With both EVs and renewables expected to continue increasing in the coming decades, copper has its role to play in decarbonization.

Circular economy is at the top of the policy agenda

Clearly the world will need more resources in the future because new technologies enabling decarbonization will require steady flows of raw materials. This means recycling will be increasingly important. Circular economy is already a key global policy priority, particularly in Europe where a new circular economy action plan is in the works.

For copper, progress has already been made. The International Copper Study Group (ICSG) estimates that, on average, 35 percent of current global copper use comes from recycled copper. Some industry players are already working on solutions to make the raw materials sector even more circular.

- In Germany, Aurubis is extracting CO2-free surplus heat from copper production and delivering it to HafenCity East, near Hamburg, through a 3.7-kilometer (2.3-miles) pipeline. The project saves 20,000 tonnes of CO2—equivalent to about 10,000 cars driving 12,000 kilometers (7,450 miles)—per year. The project means HafenCity East is the first city neighborhood to be entirely supplied with CO2-free industrial heat.

- In Belgium, Metallo continues to innovate to make copper production more circular. Its ground-breaking new plasma oven allows the company to recycle low-grade materials in such a way that they can be turned into high-grade metals and minerals.

More initiatives like these, as well as an expanded focus on urban mining, will be needed to ensure a fully circular economy. At the same time, policymakers will need to take a holistic approach to ensure the right regulatory framework is in place.

Responsible sourcing and copper demand need to be addressed

Recycling alone will not be enough to meet the rising copper demand. More resource extraction will be necessary in the future. Demand for copper alone is expected to increase by around 50 percent in the next 20 years.

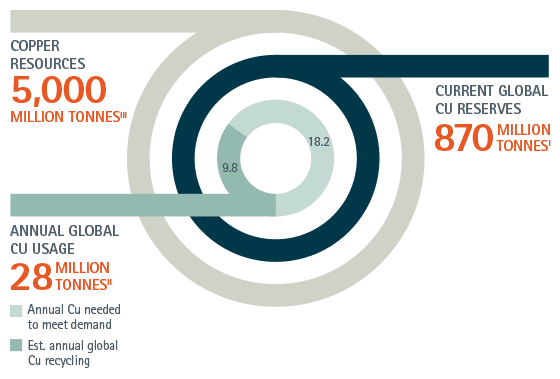

However, some have wondered whether there will actually be enough copper to meet the rising demand in the future. The answer is yes. Current global copper reserves are estimated at 830 million tonnes (US Geological Survey [USGS], 2019), while annual copper demand is 28 million tonnes. Furthermore, according to USGS data, since 1950 there has always been, on average, 40 years of copper reserves available and over 200 years of resources, which include reserves, discovered and potentially profitable deposits and undiscovered deposits predicted based on preliminary geological surveys. These copper resources total 5,000 million tonnes (USGS, 2014 & 2017).

In addition, how this material is extracted has become an increasingly important issue. Sustainability and responsible sourcing are both big priorities for the copper industry. This is why the Copper Mark was launched this year. This initiative works as an assurance system for responsible copper production. It introduces a credible verification of practices at copper production sites, including mines, smelters and refineries, enabling informed decisions on material use and facilitating a more sustainable production in the copper industry.

Apart from this industry-wide initiative, individual companies are also paving the way ahead.

Anglo American set out requirements that all of its suppliers are expected to meet, including protection of the environment and respecting labor and human rights, encouraging suppliers to integrate the “Zero Harm” principle to people, society and the environment. Meanwhile, Teck has built relationships with indigenous peoples in regions where it has operations, including Canada, Chile and the United States, where they can be found within or adjacent to indigenous people’s territories. As such, Teck created a company policy to ensure respect for the rights, cultures, interests and aspirations of indigenous peoples, built collaboratively with their input and guidance.

These initiatives represent a starting point, but more needs to be done to meet the challenges of responsible sourcing and production. This will continue to be a top priority in 2020 and beyond as sustainability drives the policy debate across the globe.

Breaking the Silos: Cooperation Across Industries is Needed to Address Climate Change

Written by: Steve Kukoda, Executive Director, International Copper Association

The world showed its commitment to COP and climate change by quickly finding an alternative in Spain for COP25. Not having such a meeting at a critical time for the planet would send the wrong message. As this critical climate conference approaches, one of the many industries that will be part of the discussion is the raw materials sector. The copper industry is working to address the impact of mining on the environment, through initiatives such as responsible sourcing and production. However, if climate change is to be dealt with properly and for the Paris Agreement goals to be reached, different industries must work together, as no single industry can tackle climate change alone.

The world showed its commitment to COP and climate change by quickly finding an alternative in Spain for COP25. Not having such a meeting at a critical time for the planet would send the wrong message. As this critical climate conference approaches, one of the many industries that will be part of the discussion is the raw materials sector. The copper industry is working to address the impact of mining on the environment, through initiatives such as responsible sourcing and production. However, if climate change is to be dealt with properly and for the Paris Agreement goals to be reached, different industries must work together, as no single industry can tackle climate change alone.

The world is already working to decarbonize. The technologies and innovation used in this process, from efforts delivering greater energy efficiency to more renewables and electric vehicles (EVs), will all require more natural resources, including copper. According to the World Bank’s 2017 report on “The Growing Role of Minerals and Metals for a Low Carbon Future,” demand in metals should rise tenfold by 2050 with a significant shift to a more decarbonized economic system. Demand for copper alone is expected to rise by up to 40 percent by 2035.

Despite the higher demand for copper a decarbonized economy requires, there is enough copper to meet this demand. According to the United States Geological Survey (USGS), copper reserves amount to 830 million tonnes, while resources, which include reserves, discovered and potentially profitable deposits and undiscovered deposits predicted based on preliminary geological survey, could exceed 5,000 million tonnes. It is widely anticipated that current and future exploration of copper will reveal an increase in both reserves and known resources. USGS data also indicates that since 1950 there has consistently been around 40 years of copper reserves and over 200 years of resources left due to regular new discoveries.

Demand can be partly met by recycled copper, especially as it can be recycled without losing its properties. In its 2018 World Copper Factbook, the International Copper Study Group (ICSG) estimates that, on average, 35 percent of global copper use comes from recycled copper.

Even with this recyclability of copper, the increase in demand means more extraction will be needed in the coming decades. While there are emissions to produce copper, its efficiency properties mean that copper-containing products operate more efficiently and with a lower carbon footprint. Producing one tonne of copper emits around 3.5 tonnes of CO2 while products using that one tonne emit between 100 and 7,500 fewer tonnes of CO2 thanks to the properties of copper.

However, the impact on the environment from more extraction still needs to be addressed. This is why the copper industry developed the Copper Mark, which was designed to assess the performance of copper mines and refineries against responsible production criteria and verify performance to push the industry toward more responsible production.

Individual companies in the copper industry are also taking initiative in terms of responsible sourcing and reducing the impact of mining. For example, Boliden is using volcanic clay in an innovative way to reclaim a closed mine in Sweden. Freeport-McMoran is innovating by using artificial intelligence to increase output by 90,000 tonnes, using data from sensors around the mine to improve efficiency without having to buy more heavy machinery and equipment. Meanwhile Anglo American implemented a new strategy addressing sustainability and its global footprint. The new strategy includes reducing emissions and increasing efficiency but also reducing freshwater use by 20 percent by 2020 while at the same time recycling 75 percent of all water used at its mines.

These initiatives are a great start, but no industry can act alone. Different sectors working in their own silos will not solve a universal problem like climate change. As COP brings global leaders under one roof to focus on solving this problem, different sectors must also devise joint actions.

Some key initiatives facilitating cross-sectoral collaboration are already live, including United for Efficiency, a global effort to support emerging economies to incorporate more efficient appliances and equipment. The International Copper Association is a founding member, along with the United Nations and the UN Environment Program (UNEP). This project brings together manufacturers and other technical organizations to achieve its goal of greater energy efficiency. Another example is the Three Percent Club, a coalition of countries, businesses and international organizations that aims for a three percent increase in energy efficiency per year.

COP itself fosters these kinds of initiatives, such as the Sustainable Innovation Forum (SIF). Dating from COP16 in 2010, the SIF gathers over 600 delegates from the public and private sector each year to work toward accelerating action on climate change and meeting national commitments.

These are good examples proving different stakeholders can be brought together under a common initiative to reach an overarching goal such as greater energy efficiency to address climate change. Furthermore, they show that cross-sectoral industry cooperation is possible and can lead to significant action to reduce emissions.

The International Copper Association is committed to addressing climate change within the copper industry itself but also through cooperation with other sectors. All industries in the raw materials sector and beyond must work together if the global Paris Agreement climate goals are to be achieved. Ongoing initiatives show collaboration is possible but needs to be expanded beyond this small circle of businesses to avoid the most devastating effects of climate.

Introducing Michèle Brülhart, Executive Director of the Copper Mark

The International Copper Association (ICA) is pleased to announce Michèle as the first Executive Director of the Copper Mark.

With over 10 years of experience working on the design, implementation and independent assessment of sustainability standards, Brülhart has evaluated and assisted companies at every level of the supply chain—from raw material to end product—and across multiple materials. She was previously the Director of Innovations at the Responsible Minerals Initiative (RMI) and served as the Head of Auditing at RCS Global for several years. Prior to her work at RCS Global, she held roles focused on responsible sourcing at Underwriters Laboratories, the German Center for International Cooperation (GIZ) and STR Responsible Sourcing.

Brülhart assumes this important role heading the Copper Mark as investors and consumers of copper increasingly demand products with lower carbon footprints that require fewer resources and are constructed safely and responsibly by fairly treated workers. Under Brülhart’s leadership, the copper industry will continue to coordinate closely with the OECD, RMI, ICMM, LME and IRBC to meet due diligence guidelines and help as many copper industry members as possible commit to sustainable and responsible operations.

As Executive Director of the Copper Mark, I look forward to partnering with members of the copper industry and others to drive positive change through expanded commitment to responsible production standards,” said Brülhart.

“On behalf of the members and staff of ICA, I am excited to see Michèle Brülhart become the first Executive Director of the Copper Mark,” said Tony Lea, ICA’s President. “We look forward to seeing this important program grow and prosper under her leadership.”

ICA has been working and consulting with external stakeholders continually since February 2018 to ensure the Copper Mark incorporates their feedback, and with Brülhart at the helm, the project’s next major milestone will be the launch of the formal application process in 2020.

More information about the Copper Mark and its goals can be found at sustainablecopper.org and coppermark.org, and to receive updates about the initiative’s progress follow us at @ThinkCopper.

Copper Demand & Long-Term Availability

Despite an ever-increasing demand for copper, there is more of the metal available today than at any other time in history. This, together with the ability to infinitely recycle copper, means that we are extremely unlikely to deplete our copper supply.

The future availability of minerals is based on the concept of reserves and resources. Reserves are deposits that have been discovered, evaluated and assessed to be profitable. Resources are far larger and include reserves, discovered and potentially profitable deposits and undiscovered deposits predicted based on preliminary geological surveys. Copper is naturally present in the Earth’s crust.

According to the United States Geological Survey, Copper reserves amount to 870 million tonnes, while resources could exceed 5,000 million tonnes (USGS, 2020). It is widely anticipated that current and future exploration of copper will reveal an increase in both reserves and known resources. United States Geological Survey data indicates that since 1950 there has always been around 40 years of copper reserves and over 200 years of resources left.

View or download full infographic here.

More detailed information, resources and materials are available on copper recycling, ICA briefing note on copper’s long-term availability and copper stocks and flows.

7 Key Ways to Make Buildings More Efficient with Copper

Written by Steve Kukoda, International Copper Association.

When you think of copper what do you see?

For many people, the full story starts and ends at the mine. Copper, however, is closely linked to global sustainable development – perhaps more so than any other metal or material.

Producing one tonne of copper on average emits 3.5 tonnes of CO2. Seventy percent of copper goes into electrical applications. Because of copper’s amazing efficiency, these products will emit 100 to 7,500 fewer tonnes of CO2, for a mitigation factor between 20- to 1,500-to-one.

The three pillars of the clean energy transition are renewable energy, e-mobility and energy efficiency. The clean energy transition can be measured in kilos of copper. Renewable energy uses 4-to-12 times as much, and EVs use 3-to-4 times as much. To make products more energy efficient, efficient conductors are needed, and copper presents an extremely efficient option

Planning a building requires decisions that will impact the next 50 – 100 years. Choosing an inferior conductor is a choice to be less efficient. The more copper used in a building, the more energy efficient it is. It basically does more with less energy. Efficient buildings have a smaller carbon footprint and provide a healthier environment.

Copper has 128 possible uses in green and healthy buildings contributing to accreditation by LEED, ASHRAE and WELL. Copper’s versatility is a plus for Better Buildings, from structural necessities to aesthetic adornments, including roofing, wiring, plumbing and lighting.

Here are 7 key ways to make buildings more efficient with copper.

- 1. Electric Vehicles. A 2017 report by the Institute for Electric Innovation estimates 5 million charging stations will be needed to support the 7 million EVs on the road by 2025. Copper has a primary function in both charging stations and EVs because of its superior durability, reliability and conductivity. Copper wiring in EV charging stations ensures the fastest possible charging times.

- 2. Active transportation. The sustainable building community can promote occupant wellness by tangibly encouraging alternative commuting methods. Both LEED and WELL promote showers and changing facilities in new and renovated commercial buildings, and copper in the supporting systems makes them safer and environmentally sound.

- 3. Reduced water use through metering and consumption management. Eighty percent of all utilities choose copper for water service lines because it is reliable and recyclable and does not allow dangerous contaminants to leach from tube walls—keeping treated water safe.

- 4. Energy efficiency and management. ICA member, Aurubis, and enercity will be using industrial heat extracted during copper smelting to power the Hamburg district of HafenCity East. Using this heat will save 20,000 tonnes of CO2 per year and replace the natural gas currently used.

- 5. Renewable energy. Commercial buildings can harness the benefits of on-site renewable energy and its cost-saving advantages for owners and occupants. Copper is a critical component in solar energy systems due to its unique and inherent properties. It’s also integral to the electrical generators, connections and protective grounding systems of wind energy technologies.

- 6. Lighting and shading controls. The sustainable building community can provide natural light for wellness and productivity and shading for comfort. ASHRAE promotes office space shading, WELL recognizes both solar glare controls and automated shading controls, and LEED supports individual lighting and glare controls to adjust conditions according to tasks and preferences.

- 7. Indoor air quality. A study by the Healthy Buildings Program at Harvard concluded that even modest improvements to indoor environmental quality may have a profound impact on the performance of workers. ICA works with governments around the world to help them adopt minimum energy performance standards (MEPS) for air conditioners for public health, reduction of airborne bacteria and mold.

What is required to get here?

- – Investment. Energy efficiency is expected to meet about half of the Paris Agreement—more than renewables or EVs—but investment is only $250B annually. It needs to be 3-to-10 times more. This includes investment in buildings. Half of the buildings in the developing world have yet to be built. These new builds must be done thoughtfully.

- – Sustainable Mining. More demand for metals will mean more mining, even with more recycling. It is vital that resources like copper are produced sustainably. For this reason, ICA developed the Copper Mark, a program for assessing copper mines and refiners based on 31 production criteria so consumers and investors can make informed decisions about the copper they source.

- – Governments need to put policies in place that only allow efficient buildings to be built and efficient appliances to be sold. By using existing technology with the right policies, MEPS and financing, consumers and businesses will consistently make energy-efficient decisions.

Materials like copper have a critical role to play in the built environment and the clean energy transition. ICA recognizes copper’s critical role and is working globally to expand energy efficiency.